VOLCANO® 250UV Laser Optics

Systems > Laser-Lift-Off

Laser Optics for a Laser

Line up to 250mm Length using Pulsed Solid State UV Lasers

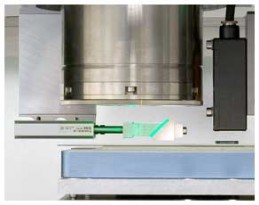

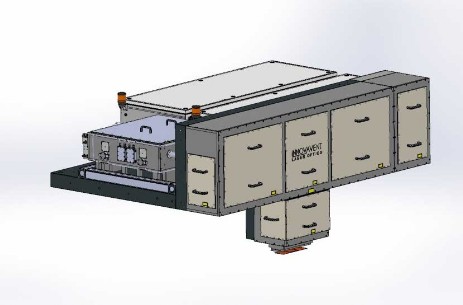

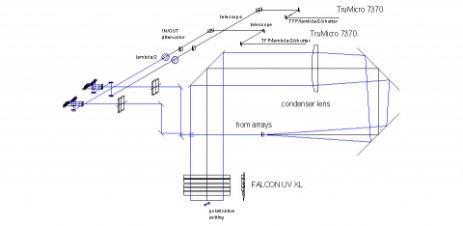

The VOLCANO® 250UV Laser Optics is built into a solid granite structure. Two laser beams can be combined to obtain high energy density. The beams are processed by independent telescopes and combined by a specially designed homogenizer. The combined laser beams are homogenized into a 250mm long line beam with a typical width of 20 - 30µm. The FALCON 250UV projection lens assures a uniform line width and the large depth of focus which trouble-free production requires. The 250mm long line provides >300mJ/cm² in a 30µm wide line with two TruMicro 7370.

Scope of Application

Laser lift-off (LLO) processes are in use in the electronics industry for the production of high brightness LEDs, a market with a fast growing volume due for instance to the increasing use of energy saving room illumination. Besides the production of LEDs, LLO processes experience an increas-ing demand for the production of flexible displays for TV products, smart-phones, smartwatches, tablet computers and electronic books. For these displays the functional film is produced on a rigid and flat glass sub-strates and subsequently transferred to a flexible carrier like a polymer foil by debonding it from the glass transport substrate.

Another application for LLO is the production of 3D stacked semicon-ductor devices. Devices manufactured on thin wafers of several 10µm thickness are stacked vertically. To process thin wafers they are often bonded to support carriers. Traditionally these carriers are silicon wafers. Debonding the thin device wafers from the thick support carriers after pro-cessing is a mechanical process during which a remarkable amount of mechanical stress is applied to the thin wafer. If the silicon carrier is replaced by a glass carrier, a laser lift-off process can be used which allows much gentler debonding with subsequently higher yield.

| Technical Data VOLCANO® 250UV | ||

| Wavelength: | 343 nm | |

| Line length: | 250mm (top-hat-Profil) | |

| Line width: | 20-30µm FWHM (Gaussian profile) | |

| Homogeneity: | +/-6% (p2p~6 Sigma) | |

| Energy density: | up to 330mJ/cm², up to 500mJ/cm² @ 20µm FWHM | |

| Pulse duration: | 15-20ns FWHM, can be extended by delay trigger scheme | |

| Repetition rate: | 10kHz | |

Scan speed: | 50 - 150mm/s, depending on substrate | |

Laser: | 2x TruMicro 7370 (Trumpf Lasertechnik) | |

| Diagnostics: | laser power meter, substrate power meter, substrate beam profiler, fast photodiode | |

Other line sizes and other configurations on request. | ||